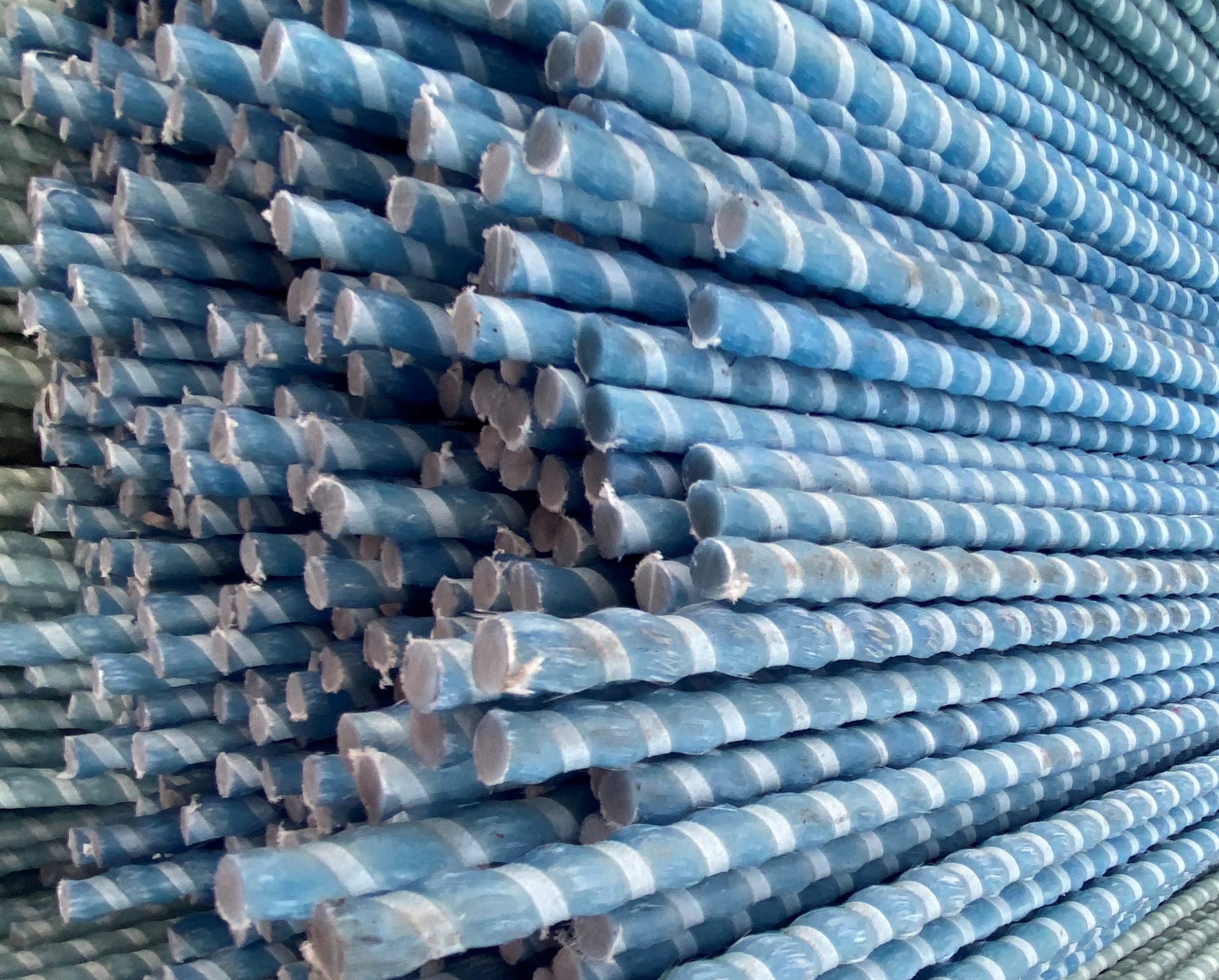

A Better Alternative to Galvanized Steel of Tempered Steel Rebars

Built to Last

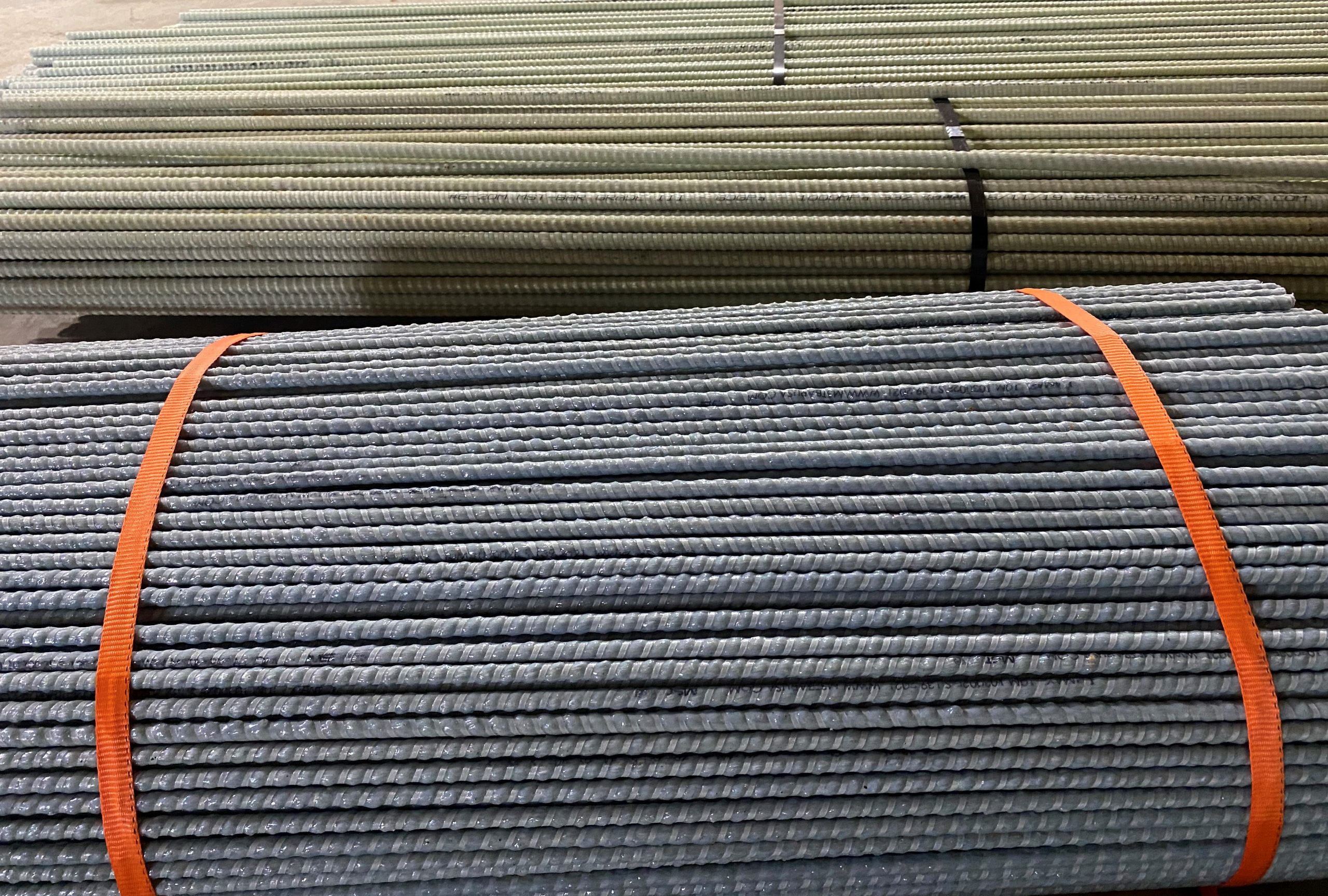

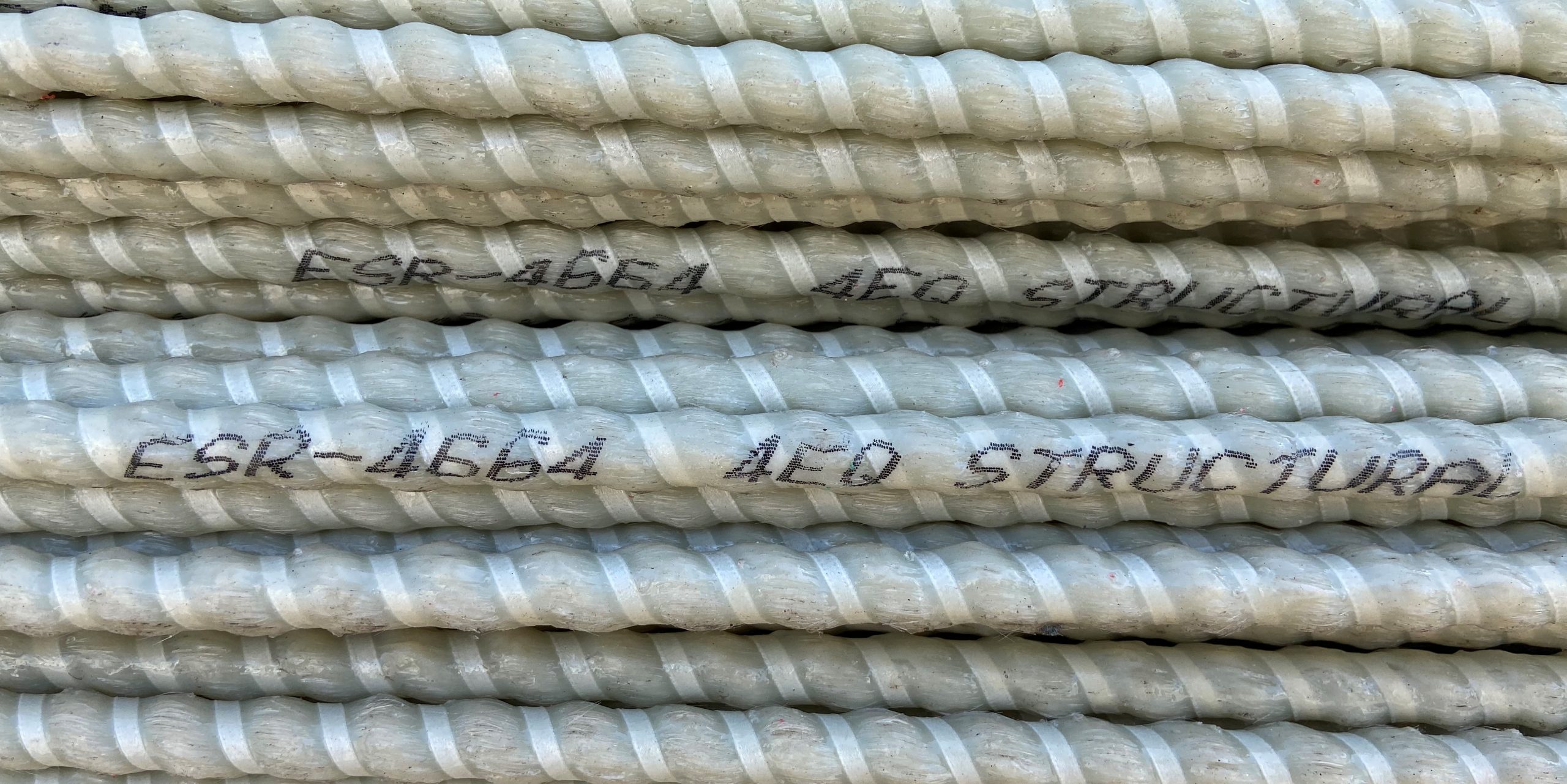

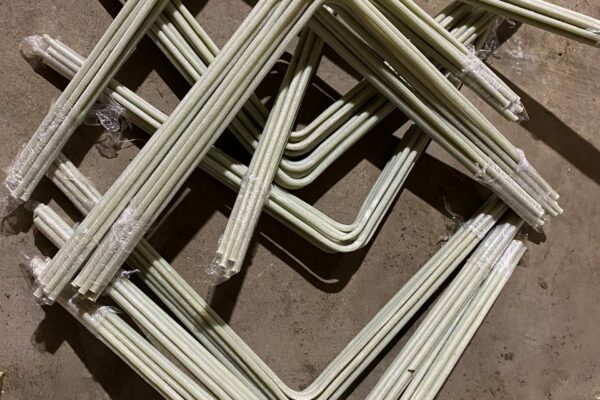

MST-BAR® is an industry leading GFRP (Glass Fiber Reinforced Polymer) Rebar built to last. It is strong, lightweight, sustainable, and doesn’t corrode. MST-BAR® is non-corrosive and non-conductive and is the perfect reinforcement solution for environments exposed to water, salt, humidity, high voltage currents, and magnetic fields. With a life span of more than 100 years, MST-BAR® is more durable & a much longer lasting solution over galvanized, epoxy coated and stainless steel. MST-BAR® is approved & manufactured in compliance with ACI 440.

Products Overview

Key Advantages

Resources & Services

Project Highlights

Contact Us

For more information regarding specifications, pricing and availability please fill out the form below. Our team will be in touch with you shortly.

Call Us Today

Get more information regarding specifications, pricing and availability.